|

|

|

The Special Engineering Bureau with a Pilot Plant (SEB PP)

KARPUSHIN Mykola Olexandrovych Director of the special engineering bureau with pilot plant of the V.I. Vernadsky IGIC NAS Ukraine phone: 424-80-80 e-mail: karpushin@ionc.kiev.ua The pilot plant of the Institute of General & Inorganic Chemistry of the Ukrainian NAS was established in 1972; the organizer and first director of it was Doctor of Technical Sciences V.I. Stetsenko. On the basis of several departments of the pilot plant, a special engineering department with pilot production (SED with PP) was set up. Since 1994 N.A. Karpushin heads it. The main directions of the activities

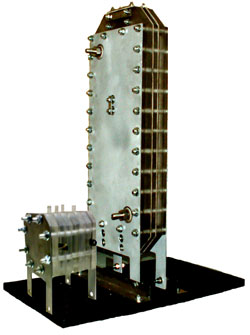

Experimental products and the technologies developed in collaboration with the Institute are used at Ukrainian and foreign enterprises owing to the unique properties of materials and articles and to the fundamental novelty of the technological processes. They include the following developments performed during the past two years: dielectric substrates for microwave devices, resonators for various purposes, PTCK ceramic heating elements for household and industrial equipment, production of high-purity titanium (IV) dioxide, titanium-manganese oxide anodes for cathodic protection systems for underground pipelines, high-purity zirconium and aluminium oxides, production of sorbents: zirconium phosphate with a static exchange capacity for Na (at pH 7) of over 2.6 g.eq./kg, refinement of a technology and manufacture of lots of heat carrier (use at down to minus 37 0C), tested elements of technology for complex processing of red mud from alumina refineries, etc. On the basis of scientific developments performed by the Institute's departments, the following devices have been designed, made and introduced at Ukrainian enterprises:

|

|

Main | History | Leadership | Departments | Science activity

Councils | Journal | Center the scientific equipment | Contacts |